By joining you will help ensure that we can continue to provide this service

JOIN HERE!

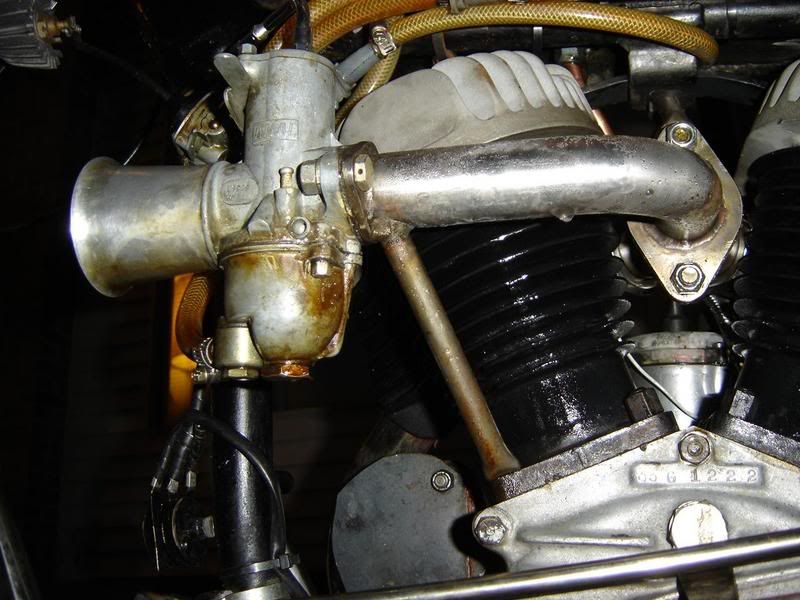

Type 255 Kompressor

- Bruce Frey

- Posts: 536

- Joined: Fri Oct 27, 2006 3:00 am

Type 255 Kompressor

While it may cool the fuel/air mix a bit, I think the primary intended purpose of finned nut is to reduce the head temp around the intake valve.

The end result is, I suppose, that if you cool one (head at intake valve), it will alos provide some cooling to the other (fuel air mix).

It would be interesting to know how well it actually worked.

Has anyone read how much boost the superchargers created?

Best regards,

Bruce

-

bmwmyplace

- Posts: 149

- Joined: Mon Feb 26, 2007 6:23 am

Type 255 Kompressor

If you look at the BMW archives you will probably not find one with fins on it ....typial of some restorers , they put a personal touch to their work, and nothing more PG

Type 255 Kompressor

however, they do drop pressure although hopefully a tolerable amount

certainly more pronounced in turbo applications but the most efficient mechanical blowers weren't available back then

I think they are the teflon tipped screw types and the Germans didn't patent them until the 60's....... and I am pretty sure that particular patent did not include teflon tips as they didn't seem to come about until later

probably due to materials availability and the difficulty in machining a precision dovetail on a helix to accept the tip

making, starting with only a notion, a three lobed screw pair today along with machining it to run teflon at very tight clearances...... it really affordable and doable

so my opinion is anything one can do to dissipate heat from the intake charge and engine........ with better being to minimize heat transfer into the engine.. and use it in making the piston going DOWN and then exit the the exhaust

is a good thing but for forced fed applications....... some form of inertial/adiabatic/intercooling does minimize both thermal and mechanical losses involved with the process

for the bmw the toss up is do you turn the heads around and have to deal with directing airflow to the exhaust....... probably worth it for a blown application but my guess is that only salt flats type comparison runs would tell the tale

my opinion of the cooling fins for a blown app is that the whole intake tract would benefit and just one tiny clamp at the head is likely just candy

and yes the runners should be brightly polished or chromed externally

- Bruce Frey

- Posts: 536

- Joined: Fri Oct 27, 2006 3:00 am

Type 255 Kompressor

In looking through the photos in the BMW Archives, the finned nut on the intake of the type 255 engines is not present, so I think the comment that it was a restorer's embellishment is probably correct.

Looking at the other photos of supercharged prewar racing machines in the Archives, it appears that at least 3 different types of blowers were used on the older (late 20s to mid 30s) OHV racing engines. All were mounted above the transmission and I can identify one as a Roots type, another looks like is a centrifugal but I have no idea how it is driven and the third is a mystery.

Interesting stuff.......

Best regards,

Bruce

Type 255 Kompressor

bearing, shaft, and unit speeds are astronomical and they add quite a bit of heat if they truly operate where they are efficient

many did not have the necessary added complication of a sprag or one way clutch driving them, and consequently, engine deceleration was brutal to the unit and drive

I'm only speaking in general as I have no hands on experience with that BMW setup

here is a adiabatically very efficient, and highly polished, intake runner five minutes into it's thermal soak

Type 255 Kompressor

I tried to do a screen shot of the part of the DVD but when I displayed it, it was blank. I had to resort to taking a digital picture of my screen and using that to display it. If I can do this right, here's a picture of what I saw. I tried to find any other photos from the archives but couldn't find anything from this angle.

If anyone has any thoughts or knowledge about this, I'd appreciate hearing about it.

Kurt in S.A.